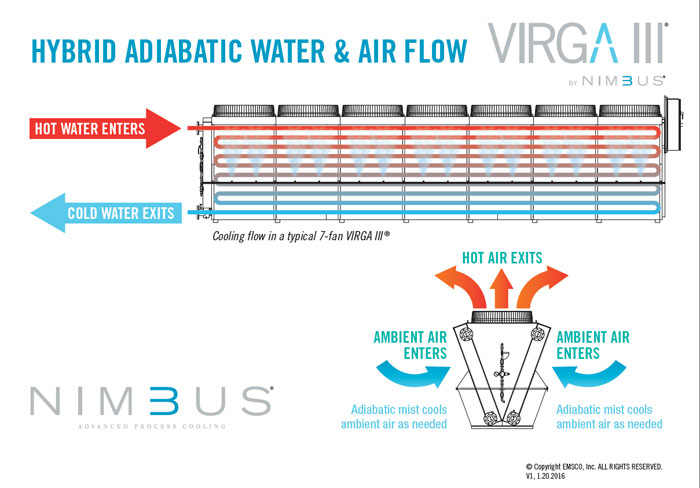

Hybrid Adiabatic Process Cooling

Hybrid adiabatic cooling technology is based on the adiabatic cooling principle of reducing heat through a change in ambient air temperature and utilizes freely available natural resources (fresh water and clean air) to regulate temperature. Hybrid adiabatic cooling systems, such as the VIRGA systems by NIMBUS, are engineered to provide customers with significant conservation benefits in the areas of water, energy, and health. These systems also feature a reduced footprint and minimize maintenance costs and requirements.

Similar to the simplicity of dry air coolers, adiabatic cooling systems circulate process water through copper tubing and large fans blow outside air across the fins cooling the process water. However, when ambient temperatures require additional cooling (typically in hottest months of the summer), adiabatic coolers are unique in their ability to pre-cool the air with a fine water spray prior to it being pulled over the copper cooling tubes. The water evaporates, lowering the air temperature and increasing the cooling of the systems at a much greater capacity than dry air coolers.

VIRGA III® & VIRGA X3™ by NIMBUS® are advanced hybrid adiabtic cooling systems that operate at optimal efficiency in high ambient and low water temperature applications. This innovative temperature control technology uses significantly less water than traditional fluid process coolers, reducing the usage and disposal of chemically-treated water, and eliminating Legionella and bacterial risks. VIRGA systems cost less to operate and are virtually maintenance free.

Water-Smart

Unlike typical fluid cooling systems that rely on a reservoir of standing water to cool, VIRGA’s hybrid adiabtic cooling system utilizes water only when ambient air temperatures are too high to cool the fluid to the desired temperature with the fans alone. During the hottest months of the year, an intermittent fine spray of water is released to cool the air before it enters the unit. In cooler months, VIRGA hybrid adiabtic coolers function as a dry air cooling system eliminating sump freezing and dangerous ice buildup common with typical fluid coolers. On an annual basis, this system saves (up to 95%) on water compared to typical fluid cooling towers.

Health Benefits

Traditional open evaporative cooling systems collect cooled water at their base, which is one of the primary breeding grounds for Legionella pneumophila - the bacteria that leads to no fewer than 50,000 cases of Legionnaires’ disease annually in the United States. The hybrid adiabatic technology applied by VIRGA X3 & VIRGA III systems eliminates standing water with its fully closed coolant path and intermittent spray of fresh water to enhance the system’s cooling capacity.

Energy Conservation

Hybrid adiabatic cooling also helps customers reduce their carbon footprint with energy saving solutions. The VIRGA III & VIRGA X3 fans (EC and AC are available) turn on in stages and only run when required to maintain the desired operating fluid temperature. This system only operates when necessary and consumes considerably less energy than the fans on fluid or dry air cooling systems which run continuously.

Low Operating Costs

In addition to using the least amount of water and energy, hybrid adiabatic cooling systems occupy a smaller footprint compared to dry-air coolers and require less maintenance than traditional cooling systems. The VIRGA systems come standard with copper tubing inside the coil bundles and naturally resists corrosion due to atmospheric exposure and chemicals often found in water.