Overview

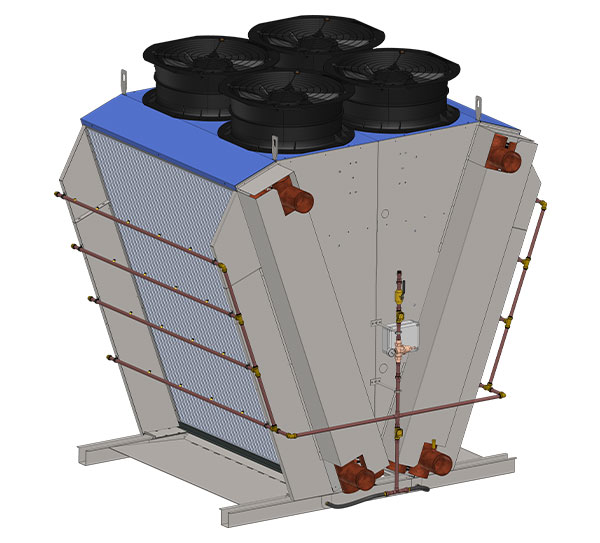

VIRGA® hybrid adiabatic cooling systems are exceptionally efficient, yielding lower operating costs and offering lower capital investment as compared to dry coolers because they require fewer units to cool any given volume of water.

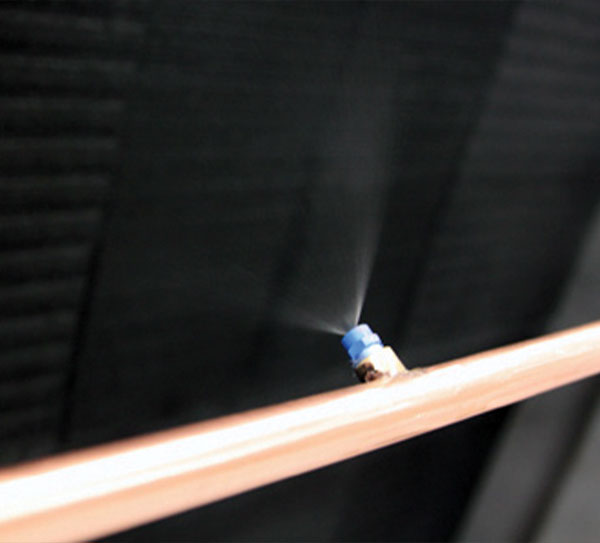

Similar to the simplicity of dry coolers, adiabatic cooling systems circulate process water through bundles of copper tubing and large fans pull outside air across the fins to cool that process water. However, when ambient temperatures get high enough to require additional cooling, the adiabatic cooling system releases a fine water spray into the air prior to the air being pulled over the copper cooling tubes. That water evaporates which lowers air temperature, offering a significant cooling advantage over dry coolers.

VIRGA control systems cycle individual fans as process water temperature dictates and ultimately activate the fine spray of water only when required. During temperate conditions, water spray activation is not required and the unit operates as a dry cooler.

VIRGA reduces water consumption up to 95% compared to open-cooling and closed-circuit towers as well as reduces energy use up to 50% when compared to dry coolers.

The hybrid adiabatic cooling technology used by VIRGA systems was born in response to regulations aimed at preventing the spread of Legionnaires' disease by replacing traditional evaporative cooling systems, one of the most common breeding grounds for Legionella.

NIMBUS was the first company to manufacture hybrid adiabatic cooling technology in the US.

Features & Benefits

- Misting Nozzles apply a fine spray of fresh water to the air entering the unit to increase cooling capacity only when required on the hottest days of the year

- Self-Draining Spray System triggers the sparge pipe to drain every time it is shut off eliminating a primary breeding ground for Legionella bacteria and winter sump freezing

- Self-Contained Water System (without reliance on a sump or a basin) saves thousands of dollars annually on chemical treatments required for traditional fluid coolers

- Fans with Smart Programming cycle on and off in stages to maintain the exiting water temperature

- EC or AC Fan Motors (with or without VFD) minimize energy consumption (VIRGA CIRRUS only available with EC)

- Stainless Steel Construction ensures years of operation

- Copper Tubing offers excellent thermal conductivity and corrosion resistance, critical in de-ionized water applications

- Marine-Grade Coating on Coils provides 26,000+ hours of salt spray resistivity and zero-growth antimicrobial resistivity

- Easy Access Lift Points are bolted to the internal structure of every fan section for quick, simple, and safe lifting and positioning

- UL/UL-C Industrial Control Panels custom-built by NIMBUS offer direct 460V, 208V, or 575V applications as standard with fully contained PLC or digital controls

- Wide Range of Heat Rejection from 5 tons to 450 tons per unit

- Minimal Footprint requires less space than traditional dry coolers

All VIRGA systems are designed, engineered, tested, and built by NIMBUS® Advanced Process Cooling in the USA.

All VIRGA systems are designed, engineered, tested, and built by NIMBUS® Advanced Process Cooling in the USA.

Applications

Commercial and Institutional

- Schools & Universities

- Hospitals/Health Care

- Government & Military

- Airports/Transportation Hubs

- High Rise Towers

- Shopping Centers/Retail

- Restaurants

- Correctional Facilities

- Casinos

INDUSTRIAL FACILITIES

- HVACR

- Data Farms

- Food Processing

- Wineries & Distilleries

- Grow Facilities

- Automotive Manufacturing

- Chemical Processing

- Thermoplastics

- And Others

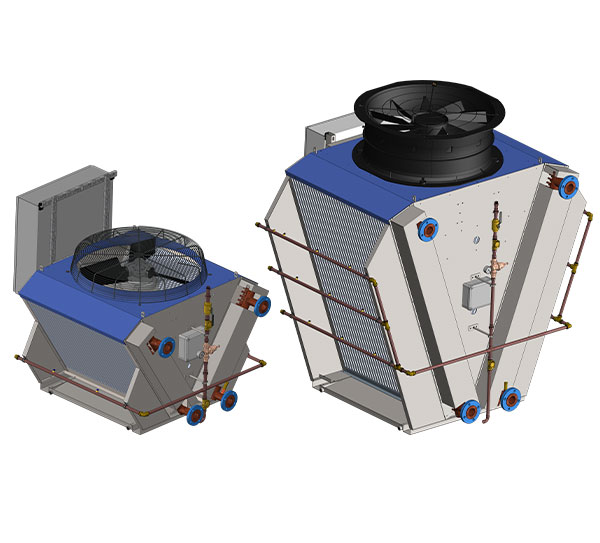

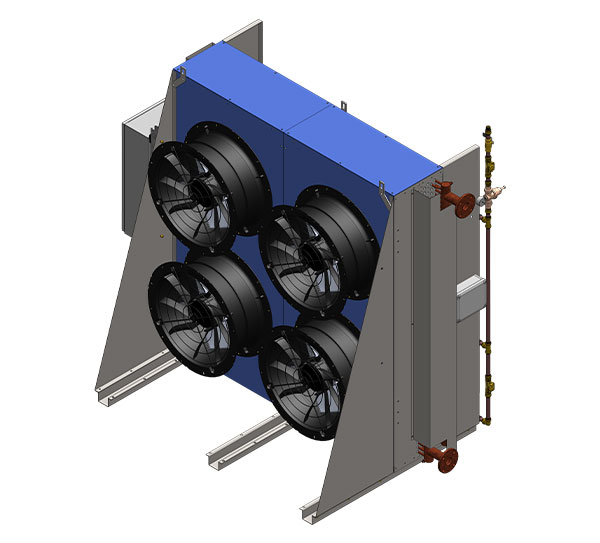

Configurations

VIRGA® CIRRUS™ for limited-height environments, features horizontal airflow design and 72.5 inch fins.

Or contact NIMBUS today at 844.NIMBUS.3 to learn which type of cooling solution is best suited for your operational requirements.

Components

Controls

All VIRGA cooling systems feature UL/UL-C Industrial Control Panels custom-built by NIMBUS (UL-Certified). Panels are installed either directly on the cooling system or remotely. Controls installed directly on the cooling system are fully contained, requiring only the primary power connection on site. NIMBUS’ cooling systems feature Type 3R-rated enclosures as standard, with Type 4 and Type 4X available as options.

VIRGA units outfitted with EC (Electronically Commutated) fans come standard with PLC controllers. Units outfitted with AC (NEMA) fans include digital controls as standard with PLC controls and VFD, or no controls available as options. Standard EC fan packages and AC fan packages upgraded with VFD and PLC controls provide fan speed modulation, while standard AC fan packages with digital controls feature “on/off” fan staging.

All NIMBUS cooling systems arrive at the installation site pre-programmed to the customer’s specifications with the leaving fluid temperature sensors installed and wired. Users can adjust the set point to the desired leaving fluid temperature.

Smart Spray

NIMBUS Advanced Process Cooling's Smart Spray System provides spray staging and fan modulation control to deliver unparalleled water and energy conservation. The Smart Spray System enables your VIRGA cooling system to smoothly achieve steady-state conditions quicker than ever before. NIMBUS' Smart Spray System minimizes fluctuations in process fluid temperature – reducing fan and spray cycles.

The Smart Spray System provides

- Enhanced water management allows for greater water conservation. Fan modulation feature (active while spray is engaged) reduces energy consumption – minimizing overall operational cost.

- Active Control System uses outdoor air temperature and relative humidity sensors to enable your VIRGA cooling system to quickly react to changes in outdoor air conditions, process fluid temperature, or heat load with precision.

- Cold Weather Advisory feature notifies you when it is time to perform pre-winter maintenance on your VIRGA cooling system.

- Innovative Humidity Sensing feature measures ambient humidity and prevents the adiabatic spray from engaging when ambient air humidity is near saturation to prevent inefficient water use and minimize water on the ground.

- Three operational modes that provide a choice among water conservation, energy conservation or a third mode which balances the conservation of both.

Resources

VIRGA III User Guide

Digital version of the User Guide included in the control panel of VIRGA III systems. This guide is trilingual (English • Spanish • French).

VIRGA Product Testing

NIMBUS Advanced Process Cooling employs a team of cooling engineers, researchers, and developers from its state of the art in-house testing facility to ensure it delivers cutting edge hybrid adiabatic cooling systems. NIMBUS’ latest innovation, the VIRGA X3, is the result of NIMBUS’ investment in its team and research capabilities.

Case Studies

Delivering Cooling For Fast Food Restaurant

When students returned to The Ohio State University this fall, they found a new fast food option in the heart of campus. Located on the ground floor of a six-story apartment building, the new restaurant's cooling includes a VIRGA III hybrid adiabatic cooling system by NIMBUS.

Advancing the Process of Cooling

With melting furnaces reaching several thousand degrees, foundries are some of the hottest manufacturing facilities in the world. Early on, the NIMBUS team was approached by a well-established, forward-thinking foundry to help cool it's process.

Enhancing HVACR Safety in Alabama

In the Southeast United States, summertime working conditions can become nearly intolerable when factory and warehouse staff are faced with high temperatures and high humidity. One Alabama company recently renovated and expanded their facility, and decided to install air conditioning in the shop area to enhance employee comfort.